LMS Highways Delivers 6 Bays Per Night on Major M20 Concrete Bay Replacement Project.

The Challenge: Why the Work Was Needed

Junction 8-9 of the M20 spans a distance of 21.6 kilometres and is the major travel corridor to the English Channel. This section of the motorway is also crucial for Operation Brock, a contraflow system designed to manage traffic disruptions across the English Channel. Operation Brock enables the M20 and other roads in Kent to remain operational during such disruptions by temporarily holding HGV traffic heading to the Port of Dover or the Eurotunnel in designated lanes, effectively transforming the section into a ‘lorry car park.’

Given the essential nature and heavy traffic load of this corridor, its imperative the road condition is closely monitored and well maintained to avoid any severe disruptions. The imminent launch of the new Entry/ Exit System of border controls added urgency to the project, leaving only a limited window of several weeks to complete all necessary concrete bay replacements and associated repairs on both the London and Coastbound carriageways.

Delivering Solutions: Scope of Work

LMS Highways last provided repairs to the M20 junction 8-9 back in 2018 in preparation for ‘Brexits Operation Stack,’ which had a similar purpose to Operation Brock. During that project, the team removed and reinstating an approximate 19 tonnes of concrete per day, totaling roughly 1,600 tonnes over a 12-weeks period.

In the latest project, which began in September 2024, LMS Highways demonstrated advanced skills and commitment to innovation. The team successfully removed and reinstated approximately 2,900 tonnes of concrete on both the London and Coastbound carriageways in just 7 weeks, a significant improvement in efficiency.

Choosing Expertise: Why LMS Highways Was Selected

With decades of experience, LMS Highways has established itself as specialists in urgent repairs and rapid concrete bay replacements. These capabilities made LMS an ideal choice for this time sensitive project, where prolonged road closures and disruptions were not viable options.

Key factors contributing to LMS Highways’ success include:

- Meticulous prior planning: Ensuring a comprehensive understanding of project requirements and constraints.

- Skilled Workforce: All staff and sub-contractors working for LMS Highways are highly trained and meticulously chosen.

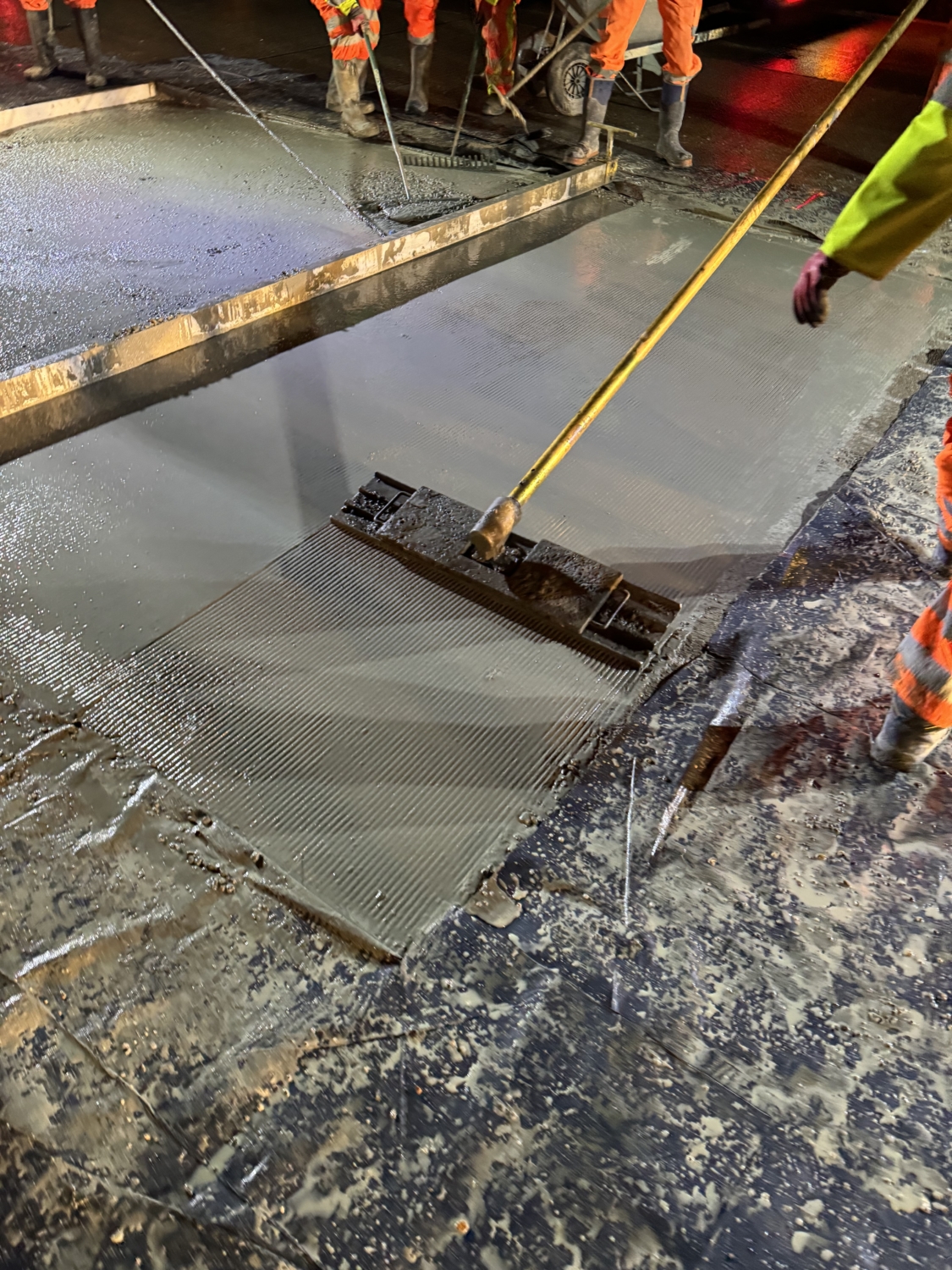

- Bespoke Equipment: We utilise bespoke plant and machinery designed for optimal performance.

- Innovative Materials: We’ll always use the most appropriate materials to fit a clients budgets and timelines. In this case we used our newly developed low carbon, rapid set concrete, Premcrete.

Results That Matter: Project Outcome

In just seven weeks, LMS Highways completed the removal and the reinstatement of over 890 cubic metres of concrete. The use of our rapid set concrete mix ensured minimal disruption to the M20 junction 8-9 and allowed the team to deliver the project within such a tight schedule.

- 44 Shifts

- 2,800+ Tonnes of Concrete Removed

- 1,060+ Cubic Metres of Concrete Installed

- 2,300+ Linear Metres of Joint Sealing Installed

The use of Premcrete concrete enabled rapid setting and minimal disruption, ensuring the project was completed within the limited timeframe. This successful delivery highlights LMS Highways’ dedication to providing innovative, efficient, and high-quality solutions for essential infrastructure improvements.

“From the start, this was a real partnership. We worked closely with LMS Highways to develop a rapid-set concrete that could genuinely shift the dial in terms of speed, carbon, and delivery certainty — and they were involved at every step. Not only did they take on the trials themselves at their own expense, but they also provided invaluable feedback that helped us refine the product in real-world conditions.

The result is a material that doesn’t just perform in theory — it performs on site, under pressure. What LMS achieved on the M20 proved that. Full-depth slab replacements delivered at pace, minimal disruption, and a clear reduction in shifts and carbon footprint. It showed what’s possible when great product meets great execution.

We genuinely believe this product can help change how critical infrastructure gets delivered across the UK — not just on roads, but in ports, airfields, and anywhere speed and reliability matter. But the truth is, it only works because of teams like LMS. Their experience, precision, and willingness to lead from the front made it all possible.”– Alvin John, Technical Sales Manager (Civils) for Premcrete